Southern Locomotives Ltd.

Their website

Southern Locomotives Ltd (southern-locomotives.co.uk)

Southern Locomotives Ltd, shareholder update, June 2021

Dear Shareholder,

It’s only two months since we last contacted everyone, but a lot has happened in this short time, some very good, some not so good!

As you probably know already Eddystone is back in service after a spectacularly short running in process. Indeed it has not been since 1990 with 257 Squadron, that a locomotive has entered traffic so quickly. Anyone who has been looking at YouTube videos taken by ‘The Southerner’ (one of our shareholders), will see from its very first test run how steam tight it was – incredibly so given the complexity and myriad pipe runs on a Bulleid Pacific. If you haven’t seen these professionally made shorts just search YouTube for Eddystone, and a whole series will come up from the transfer from Herston to Swanage, through to the loaded test runs, and on to its first revenue earning service in seven years.

Clearly the new procedures put in place at Herston under the auspices of Graham Froud have paid dividends, with Eddystone emerging from the Works only a few months late, despite it being closed for a long period of time in 2020. It has been featured on Meridian television since entering traffic.

There is also some really good news regarding 80104 which we detail below. So, to run over details of all the fleet we’ll get the bad news out of the way.

257 SQUADRON

With six Pacifics in the fleet and two which we’ve sold, we thought we would have encountered pretty much every problem which could arise with a Bulleid over the past 38 years. Not so unfortunately. Following a mysterious steam leak which couldn’t be identified, the locomotive was brought into the Works and given a hydraulic test which revealed water pouring from the main internal steam pipe which runs from the regulator to the superheater header. Obviously with the boiler full of flues and tubes the pipe is pretty inaccessible, although somehow Bailey managed to gain access through the dome and photographed the very small hole in the pipe at the tubeplate end.

34072 257 Squadron in Herston on 19th May, minus bogie. The rocker shafts which link the valve gear and the piston valves are being examined, and the regulator is being inspected. Photo: Nick Thompson

This problem we believe is a new one in Bulleid circles although we understand that Tangmere has replaced theirs recently. It’s a very solid and expensive pipe some 3/8th of an inch thick, and in this case would have been subject to thickness testing and a hydraulic far beyond maximum working pressure, only three or four years ago. Basically it’s just bad luck that at a time when we thought we could actually earn some serious hire fees to both progress projects, and pay back some loans, we are again thwarted.

If we can derive any positive news from yet another locomotive having to be transported to Tyseley at great cost and subsequent loss of earnings, it is that the solution to the problem could have been a lot worse! The boiler inspector has insisted that a new pipe is installed, rather than patched which may or may not have worked, but has agreed that it need only be welded from the outside, rather than internally as well. Both methods were used in BR days. This means that rather than having to remove the superheater header, all the elements, flue tubes and half the small tubes so that a welder could get in the boiler to gain access, only the elements need to be removed so that the superheater header can be removed. The pipe is then fed through the tubeplate and seal welded saving at least £25,000 had we had to strip half the boiler.

So, we again we find ourselves in the situation of either parking the locomotive up, with its boiler certificate ticking away, or sending the locomotive away to be repaired. Predictably we’ve taken the latter decision and we hope that shareholders will agree with this decision, despite our not actually having the money, with all current funds allocated for significant bills still to be received from Tyseley for Manston and the North Norfolk Railway for Sir Keith’s new boiler.

257 Squadron’s bogie has been stripped awaiting repairs and the axle boxes are being examined. Photo: Nick Thompson

Herston Works is not really equipped for boiler work, but with the kit that they have at Tyseley the job will be swift, although the pipe unfortunately cannot be ordered until the header is out and precise measurements taken. The manufacture of the pipe is quite complicated and at £2000 not something that we would want to pay for twice. It is very much hoped that the Squadron will be ready for traffic during October. Apart from the full overhaul of its bogie using parts from Sidmouth’s which will be completed by next month, the opportunity was taken to undertake various other jobs. These will not be completed before Manston’s low loader arrives to take 257 to Birmingham so another short spell in Herston will be required before transfer back to the Railway.

Turn the clock back to September 1990, when 34072 257 Squadron ran from Ashford to Folkestone for its recommissioning event. The loco then made a short trip to Dover. In this photo it’s seen crossing the viaduct above Bradstone Road, just east of Folkestone on its return leg to Ashford, pushing a class 73 Electro-Diesel which had also been renamed at the same ceremony. Thanks to Robert Patterson for this very unusual photo.

34070 – MANSTON

Now for the start of the good news and there’s been plenty of it. After weeks of extra testing requested by Tyseley’s boiler inspectors – all of which could have been asked for on their very first visit months ago, they finally gave the go ahead to retube last week. As of last week it was back on its wheels with all the motion on, with just the centre piston to refit. They hope to have fitted and expanded all the tubes within the next two to three weeks and prepare it for its hydraulic test. All being well, the steam test will follow shortly after. It will be transferred back to Herston for the team to complete the task of refitting all the brake gear, cab fittings etc. Some attention will be paid to the paintwork but the plan is to put it back into traffic as soon as possible so it will be in ‘weathered’ condition. Doubtless at some point it will have a complete repaint but that can happen in the future – the vital thing is now to get it back into traffic, pulling trains on the Swanage Railway and earning revenue for us.

34028 – EDDYSTONE

The good news continues with Eddystone’s return to traffic on the 25th May – just 14 days after its first steaming and featured on the front cover of Steam Railway this month. Heritage Railways will also feature Southern Locomotives in their next edition – in fact there’s so much in this one on the Company, the feature writer said that he’d not mention us next month for fear of being thought biased!

S A Smith’s seven-axled steerable trailer carries Eddystone through the chicane at Corfe Castle on its way to Norden to be railed.

S A Smith’s seven-axled steerable trailer carries Eddystone through the chicane at Corfe Castle on its way to Norden to be railed.

Fortunately our transport company of choice for the past couple of years, S.A Smith, were able to transport Eddystone through Corfe on one of their new rigs which could negotiate the tight corners en route. This saved a lot of scratched paintwork from overhanging trees and angst for the cladding and painting team at Herston, by being able to keep to the main roads. Through their competitive pricing the same company have made it a viable proposition to move locomotives into Herston for repair, rather than spending twice as long doing the same job on the coal dock so we’re very fortunate that Graham suggested them a couple of years back.

Eddystone left the Works only a few months later than originally envisaged pre-Covid, so it is testament to the loyalty and skill of our staff that resulted in the locomotive being outshopped so quickly. So thanks again to Ron Neal, Andy Crooks, Bailey England, Pete Pickering, Chris Hardy and Graham Froud, along with our volunteers for doing a sensational job. We had much assistance from Swanage Railway staff who mucked in with getting the engine ready for service, and our staff will do likewise with the M7 overhaul, – it makes sense to work as one team and get engines out of Herston as quickly as possible, regardless of who owns them.

80104

As reported previously whilst Eddystone was performing its test runs , 80104 hauled its last train on 11th May when its boiler certificate expired. To the end it was working well and we need to thank Graham and helpers for ensuring that our Standard remained in traffic for the maximum time permitted – certainly in its latter life many unpleasant visits had to be made into the firebox, sometimes whilst still uncomfortably warm, to repair leaking stays.

80104 heads out of Corfe Castle on its last day in service, 11th May. Photo: Peter Milford

We were anticipating a potentially long delay for the overhaul, and were planning to organise undercover storage to minimise the costly deterioration that always occurs when locomotives are out of traffic, especially in the open air. In December you’ll recall us saying “The repairs to the copper firebox, etc, will cost a six figure sum, and we need to get other locos into service before we can fund that work – unless someone knows where there’s a money tree“ and that 80104 was always a difficult locomotive to attract funding for.

However, we seem to have found many of the branches of that money tree. One of our shareholders, a long term Swanage Railway supporter, has offered us an interest free loan to cover around three quarters of the cost of the overhaul to get 80104 back on the Swanage Railway, hopefully in time for the 2023 season. We are again contracting Tyseley Works who have given us a quote for the overhaul – the vast majority of the costs being extensive repairs to the copper firebox. Aware of our impecunious situation, made even worse by 257’s problem, our sponsor has kindly bought enough shares so that we have the transportation costs, and sufficient funds for Tyseley to order all the copper material that we will need. There is a probable eight month lead in time for these parts so if we’re to get the locomotive back into traffic by 2023 that order has to be placed now.

We will need contributions from both SLL shareholders who have a soft spot for ‘104, and importantly Swanage Railway supporters as well to complete the job. If we do the Railway will have its favourite locomotive back quickly, and SLL will be earning revenue which will help other ongoing restorations, as well as avoiding significantly higher overhaul bills on a locomotive which will inevitably have degraded over the years. It is really important that we get support for this project from those at Swanage and followers of the Railway who may not have considered buying a share in the past, as our shareholders have already gone above and beyond in their generosity during Covid. This most generous offer was completely unexpected, and interestingly it was something that we’ve always done automatically since day 1, that may have clinched the deal. Our sponsor advised that he really appreciates the transparency of the Company in that we’ve always strived to share all the goings on with shareholders, so that there is little if anything they don’t know once they’ve received an update. We’ve always tried to share the good news and bad news (as per this update!) and rather than grizzling about the problems which are inevitable with 70 or 80 year old machines, we just find a way of solving them. This invariably means wrecking shareholders and Directors carefully planned savings and pension plans but let’s face it – owning a fleet of Bulleids operating on two of the best lines in the UK has got to be worth it!

34053 – SIR KEITH PARK

A visit to the Weybourne Works of the North Norfolk Railway in mid-May saw work progressing on Sidmouth’s boiler – from the photograph you will see that large sections of the firebox have had to be removed – 80104 will need similar surgery. Clearly the guys undertaking this work are treating it more than just a job and without fail it will emerge a better firebox than in BR days. When some of the welding was revealed, which wouldn’t have been seen since the firebox was built, it apparently left much to be desired by modern day standards, and there is certainly no comparison to the excellent welding visible in Brocklebank Line’s firebox which was remarked upon by the boiler inspector.

Sidmouth’s boiler is inverted to enable access to the base of the firebox. Note the thermic syphons, and the large section of the inner firebox which has been cut away for replacement. Photo: Simon Troy

The hope is that it will be delivered on schedule in early 2022 to be swapped with Sir Keith Park’s boiler at Weybourne. There will hopefully be little ‘bottom end’ work to undertake following its extended stays at Tyseley in 2018/19, apart from grinding the expansion links which will relieve us of £6000. We had known about the latter job whilst at Tyseley but we just couldn’t justify the expense to do this task which wasn’t absolutely essential at the time. Sir Keith, having worked some ‘ghost’ trains in May, re-entered service on Saturday 22nd May and is expected to be quite heavily utilised for the rest of the season – all hire fees helping towards the bills arriving from the North Norfolk Railway. Apart from work on the safety valves and a problem with the coal wetter Sir Keith’s first days back in service have been successful. The turbo generator has been the biggest problem on the locomotive and clearly was in serious need of an overhaul. Whilst we like our locomotives to be as original as they can be, we did agree that it was currently best to use a system that the owners of P&O designed, with ’53 being fully sufficient on battery LED. This not only saved a probable £2000 on overhaul costs but also the locomotive would have been without electrics, possibly for quite an extended period if the last generator overhaul was anything to go by. By coincidence we have had to steal 257 Squadron’s generator for Eddystone as that gave up the ghost but we now unfortunately have ample time to repair it to reinstate on 257. The Spa Valley has accepted the Warner Bros. Polar Express franchise for this Christmas which hopefully will be a big earner for both them and us. Sir Keith will be the star attraction, and if the 23 day event is as successful as on other railways, the Finance Directors of both the both the SpVR and SLL will be breathing a collective sigh of festive relief!

34010 – SIDMOUTH

Inevitably with the completion of Eddystone, 257’s problems and the necessity of completing Manston and helping Graham with the M7 as a thank you for all the help SR staff have given, Sidmouth has inevitably been side-lined again. However, we are going to resolve this situation by transferring it back to Sellindge – the irony will not be lost on those who worked on it first time round in Kent! It does make sense though, in that there is only so much that the small team can do in Herston. Secondly there is nowhere on Swanage Railway property that gritblasting can take place either for environmental or space reasons, and thirdly we have to set up a gritblasting facility at Sellindge for Brocklebank Line.

It’s deja-vu again……this photo shows Sidmouth’s bogie being grit-blasted at Sellindge in 2009. We’re not sure who’s doing the blasting, but that looks like Geoff Thompson to the right. Photo: Simon Troy

As it is now necessary to have an enclosed space for gritblasting it’s all far more complicated than when we simply blasted away at anything that moved at Hope Farm. Therefore we think the most sensible way forward is to transfer the frames and commence the restoration in Kent, especially as we now have a growing team of volunteers numbering 12 who attend a minimum once a week, and some more often. As even the undersigned did much gritblasting and was even allowed in the Bluebell gritblasting container, (an honour indeed!) it would be illogical to pay a lot of money to a professional company to do a job volunteers can undertake. The frames would have to be moved to an off-site location in any case, so they may as well come to Sellindge where our team, which includes professional engineers, may be able to do further work if time permits before they return to Herston.

75050 – NORMAN

Work continues on the axleboxes which have required major work, but we understand will be ready for reinstatement within the month, enabling re-wheeling to take place. Unfortunately the company which was going to cut the new foundation ring for the firebox by water jet has folded, so another is being sought. As we’ve remarked in the past this locomotive has proved to be the most difficult of overhauls but we trust the finished result in 2022 will be worth the wait.

35025 – BROCKLEBANK LINE

Since our last update the team have continued to not only dismantle the locomotive, but to also transfer those smaller parts we’re removing and that need gritblasting to the guys near Canterbury, from whom we’re also buying some very useful gear. In very difficult conditions (in its current location) all the main driving springs have been dropped with their ancillary fittings and we are currently jacking and packing the locomotive – the trailing truck is now free as is the bogie. This week we’ll be lifting it further in preparation for the big lift when we move the frames and wheels etc. to our new position nearer our workshop/containers. The crane will be an expensive exercise so we have to ensure that all the axleboxes are freed up to save time on the day – this means a lot more jacking and packing but fortunately we have a good source of decent sleepers and a lot of volunteer muscle. We’ll be sharing crane costs as other organisations on site will be wanting to use it as well.

Some of the Sellindge Team. From the left: Harry and Alan Highman, Roy Carlo, Mike Price, Peter Spowage, Simon Troy, Phil Casey, Hugh Topham, Bob Waterman. Photo: Martin Stables

As hoped for the boiler inspector’s conclusion was that we have an exceptionally good boiler with a firebox that needs little work other than in the corners. Had it been stored in such a way as to prevent water pooling behind the tube plate, the major task of replacing the front tubeplate and inserting a patch on the front bottom end of the barrel would probably not have been necessary either.

Some of the team have continued with the Herculean task of clearing up our areas of the site with the help of our neighbours – by July/August it will hopefully be unrecognisable from the site that we arrived at last June following lockdown. If anyone would like to visit please let the undersigned know – we’re pretty much guaranteed to be there every Tuesday as a minimum.

As you will note from all of the above, the pace of things hasn’t slowed down at all and we are adapting to changing circumstances. Because of the generosity of our shareholders, we weathered Covid extremely well and because of our decision to have a Kent based operation as well as Dorset based, we’ve welcomed many new supporters, especially from the Spa bringing in much needed revenue, as well as a couple of extremely valuable volunteers at Sellindge. Peter Spowage who joined us early last year is a driving force in our South Eastern division and quickly became an invaluable member of the team, whilst Roy Carlo with a long legal background has already arranged various important contracts and agreements for us with little notice, as both Nic and Tom have had to step back to a certain extent from undertaking legal work for us for various reasons.

The black background to the nameplates reflected Eddystone’s appearance immediately after rebuilding at Eastleigh. All agreed that the finish of the loco’s paintwork was our best yet. A big well done and thank you to the cladding and painting team led by Dave Ensor, who also took this photo.

Whilst social distancing has been in force there has been a much restricted volunteer workforce in Herston. Hopefully this will gradually relax but Nick Thompson’s volunteer form which is accessible to all will be retained (Contact nicksidmouth@gmail.com for the link). In this way Graham is able to see who and how many people are planning to come so that jobs can be found for everyone. It is clearly not so easy for him when locomotives are in the last throes of being completed, and there is nothing worse than people driving a considerable distance and not feeling that they’ve done a decent days work. (Something that certainly doesn’t happen at Sellindge!). For example, all of 257 Squadron’s superheater elements need to be released to save us paying Tyseley staff for same, so if anyone’s feeling like doing a pig of a job please let Graham know – the Works is open Monday to Thursday. Tuesdays and Thursdays tend to fill up fast. As usual I may have forgotten to give new shareholders the password to access the ‘shareholders’ section of the website – it’s 34010sidmouth (34010Sidmouth also works). Apart from the link to download a share application form, it isn’t very exciting, showing only the dates and times of our AGM, and Footplate Days. Please also let me know if you haven’t received a promised Richard Green print or a share certificate. The latter are now issued once a month when the monthly bank account has been scrutinized to see which standing orders have reached £250 – not a quick job when banks with apparently infallible computer systems continually make errors.

In conclusion, we hope that shareholders agree with the various decisions we’re making, and will have to continue to make, to adapt to ever changing circumstances. We really hoped that in this update we wouldn’t have to report financial problems, but perhaps the shock of not being asked for funds would have been too much for our older supporters who have helped us through many trials and tribulations for nearly four decades. This time it’s 257 Squadron in trouble – definitely something we didn’t see coming!

Thanks as ever for all your support.

Best Wishes from all Directors,

Simon

Here are a couple of reminiscences from Tom Rayner and Nick Thompson:

Working the “Bournemouth Belle”

On the 17thMarch 1963, Nine Elms fireman, Jim Lister, found himself working the “Bournemouth Belle” on its return journey from Bournemouth to Waterloo on that day. In one of the recorded conversations that I had with him, he recalls what happened on the trip and starts with a few of his other memories involving this very prestigious train: – During the early 1960’s, the Bournemouth Belle was worked by Bournemouth men during the week but was a Nine Elms duty at the weekends. The top link would work the train on the Saturday and the number 2 link or pilot gang, as it was generally called, would work it on the Sunday. In terms of who worked the train, there was no question of a particular crew being picked. It was all decided by a rotation roster and when your turn came up, that was it! Usually, one of the best available Merchant Navy locomotives would be allocated to the train and as the departure time off the depot was 12 o’clock midday, the engine would normally be cleaned the day before.

35007 Aberdeen Commonwealth Line hauls the down Belle under Twin Bridges, just west of Woking in 1964. As usual the webmaster didn’t think to record the date, though it was probably during the school holidays!

I have one or two interesting memories of the train and the first is an unusual one. I remember an occasion when a special stop order was issued for Beaulieu Road Station and this was to enable Lord Montague to alight there! The order was quite explicit that the driver should ensure that the third coach from the front should be stopped so as to give access to the platform. Another memory is of the almost routine practice at that time of giving the driver and fireman a glass of light ale when the down train stopped at Southampton Station. One of the Pullman Car stewards would come walking down the platform with a tray with the drinks on it and we would consume them with relish! Of course, by today’s standards, this would not be allowed but the railway was quite different in those days and it is quite amusing looking back on it! I worked the Belle on a number of occasions and most of these were routine trips. However, my driver, Bill Turner, and I were faced with an irritating problem when we were in charge of the train on the 17th March 1963. In the morning, we worked a train down to Bournemouth. This was the 11.30am from Waterloo to Bournemouth stopping at Basingstoke, Winchester, Southampton and numerous other stations on the way. We arrived at Bournemouth West at 2.20 in the afternoon and then ran our engine, a Standard Class 5 No 73081 into Branksome Loco where we turned on the triangle and left her for servicing. We then made our way back to the West station to work the up Belle which left at 4.40pm. Our engine was No 35030 Elder Dempster Line, a Nine Elms engine which I knew well and she was generally reckoned to be “a good ‘un”. The first part of our journey was uneventful and we were making good time but as you passed through Brookwood Station in those days, there was a crossover from the electrified local line to the up through line and this brought the conductor rail with it. From this point onwards, there was a conductor rail on all lines leading into Waterloo.

A posse gather around the Merchant Navy hauling what was to be the last Up Bournemouth Belle to be steam hauled. The webmaster was there, but having ‘copped’ every MN some years previously he omitted to record the number (it looks like 35023 Holland Afrika Line) nor the exact date.

Anyway, as we had just passed through Brookwood Station at quite high speed, there was suddenly the most almighty bang from underneath the engine. My driver looked at me with a puzzled expression on his face as if to say “What was that?” and then a little later, there was another big, big, bang. It began to dawn on us what was happening. The hopper door, which was held in place by a catch, had somehow come open and every few minutes, it would swing down and touch the conductor rail. The knock-on effect was that it was also blowing out the breaker in the electrical control thereby depriving the section of line immediately ahead and behind us of power! The Electrical Control Operator in Woking would have been aware of the situation and would probably have put the breaker back a couple of times to restore the power but he was not allowed to do this more than twice unless somebody contacted him to explain the problem. We therefore knew that we were going to be stopped. We flashed through Woking at about 80 mph but then, sure enough, on approaching West Byfleet, the distant signal was on. We were in good time and running well but we realized there was no way in which they would allow us to continue while this was happening. The home signal was also at danger and we slowed right down and stopped opposite the signal box where the signalman could see what we were doing. We indicated to him that we understood the problem and after checking the local line was clear, we jumped down on to the track. I’d got the old rocker bar in my hand and we then yanked the door closed and I then banged the catch in place behind it. The signalman could see exactly what was happening and before we had finished, he was pulling off his signals! Bill got back on to the footplate and the train was already on the move before I scrambled back to join him! After that, Bill really hammered the engine and we still managed to arrive at Waterloo right on time!

Tom Rayner.

Another Belle, or should I say four Belles?

The 75th Anniversary of Sidmouth’s naming ceremony

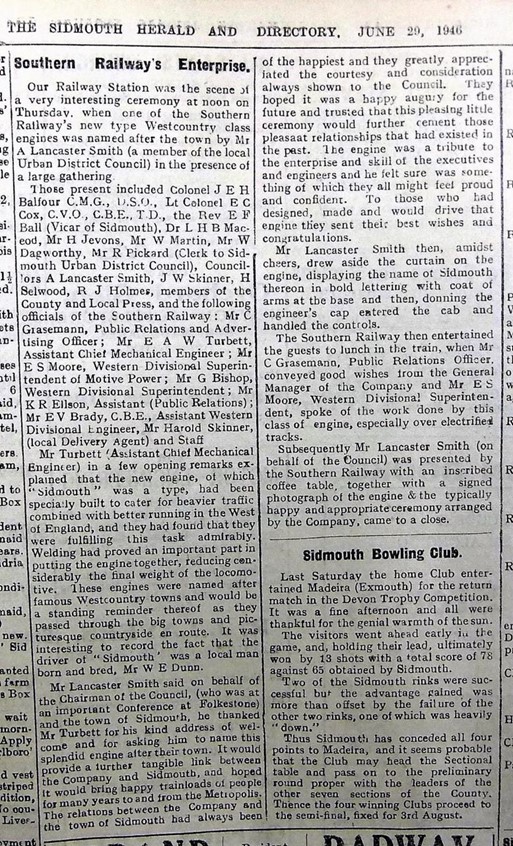

27th June marks the 75th anniversary of Sidmouth’s naming ceremony in 1946. The first batch of West Countrys were named at the eponymous location; later batches mainly missed out (a naming ceremony at Eddystone would have been worth the trip) and in many cases no crest was used.

21C110 Sidmouth got the full works; the great and the good of the town and the Southern Railway, a ceremonial coffee table, and lunch in the restaurant car which the loco had drawn to Sidmouth station. Both Sidmouth newspapers, the Herald and the Observer, reported the event, though as ever their take on railway matters was erratic. Sadly only one photograph of the event remains; far more must have been taken, but none has turned up in recent years.

Thanks to the archives of the Sid Vale Association (dating from 1846, and reputedly the world’s oldest civic society) the press reports of both the local newspapers survive, and are worth reading as a window on 1946.

A works photo showing 21C110 Sidmouth at the time of its naming. Note the lining and malachite green which lasted until January 1950.

The nameplate was unveiled by Mr A Lancaster Smith, Chairman of Sidmouth Council’s Publicity Department. We know the name of the driver and the vicar. The webmaster has met several people who say they were there on the day, and one, son of the Station Master, who was away on National Service.

Among the guests at the event was Hugh Tomalin, grandson of Mr Lancaster Smith. Hugh joined his grandfather on the footplate for a short trip on the loco, and still owns the coffee table that the SR gave to town at the event. Note that the loco carried a Devon crest, not the Sidmouth crest on the coffee table.

The Herald’s report names many of the attendees, but doesn’t include the locos number. What on earth did Mr E S Moore mean when he referred to the loco’s work on electrified line – did the journalist think the loco could take power from the third rail?

Meanwhile the reporter from the Sidmouth Observer also names lots of names, but leads with the alarming fact that the loco weighs 183 tons, It’s just as well that the Chief Civil Engineer was not invited!

And finally…..the kind of photo that makes it all worthwhile.